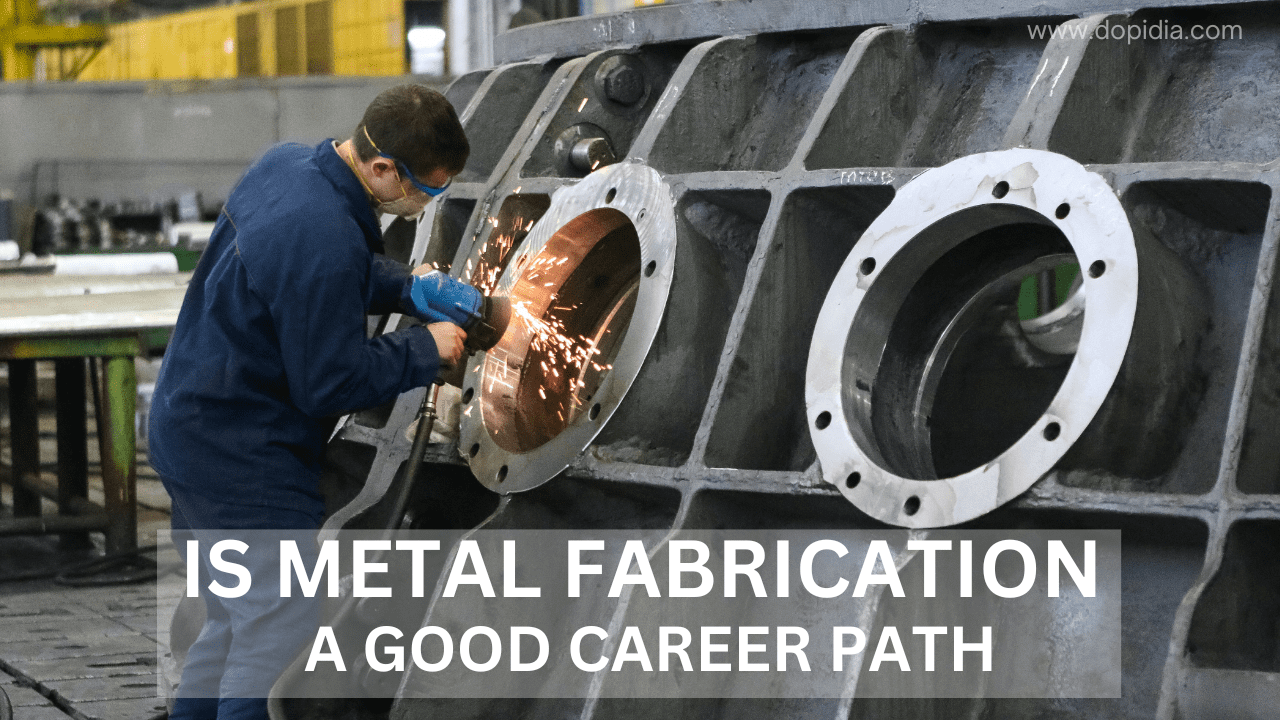

Is Metal Fabrication a Good Career Path

Introduction

In the ever-evolving job market, choosing a career path can be a daunting task. However, if you have a knack for working with your hands, a keen eye for detail, for creating, a career in metal fabrication might be the perfect fit for you. But is metal fabrication a good career path? This article will delve into the world of metal fabrication, exploring its potential as a rewarding and lucrative career choice.

What is Metal Fabrication

Metal fabrication is a dynamic and remunerating career path that offers a large number of chances for people with the right abilities and interests. In this article, we will investigate the different parts of metal fabrication as a career decision and examine the reason why it tends to be a superb choice for those hoping to seek after a satisfying and effective calling. Thus, in the event that you’re captivated by the universe of metalwork and contemplating whether metal fabrication is a decent career path, read on to find more.

Why Metal Fabrication is a Good Career Path

1. High Demand

The demand for skilled metal fabricators is consistently high. As long as we continue to build and innovate, there will always be a need for professionals who can manipulate metal into the necessary components. As per the Bureau of Labor Statistics, the work of underlying metal fabricators and fitters is projected to grow 5% from 2019 to 2029.

2. Competitive Salary

Metal fabrication can be a financially rewarding career. The median annual wage for structural metal fabricators and fitters was $40,790 in May 2022. However, with experience and specialization, this figure can significantly increase.

3. Skill Development

Metal fabrication is a skill-based job that allows for continuous learning and development. As a metal fabricator, you will have the opportunity to master various techniques and work with different types of machinery and tools. This continuous learning can lead to career advancement and higher earning potential.

4. Job Satisfaction

Metal fabrication offers a high level of job satisfaction. There is a sense of accomplishment that comes from creating tangible products from raw materials. If you enjoy problem-solving, working with your hands, and seeing the results of your hard work, metal fabrication can be a fulfilling career.

5. Variety of Work

No two projects in metal fabrication are the same. This variety keeps the job interesting and challenging. One day you might be working on a small component for a car, and the next, you could be fabricating a part for a skyscraper.

Skills Required for a Successful Career in Metal Fabrication

To excel in the field of metal fabrication, several key skills are essential. Firstly, proficiency in reading and interpreting technical drawings and blueprints is crucial. Metal fabricators should have a strong understanding of measurements, dimensions, and specifications to accurately fabricate metal components. Additionally, manual dexterity, attention to detail, and the ability to work with various tools and equipment are vital skills for a successful career in metal fabrication.

Education and Training in Metal Fabrication

While formal education is not always mandatory for entry-level positions in metal fabrication, acquiring relevant training and certifications can significantly enhance job prospects and earning potential. Vocational schools, community colleges, and technical institutes offer programs in metal fabrication, providing comprehensive training in welding, machining, blueprint reading, and other essential skills. Apprenticeships are also a popular route to gain practical experience and learn from experienced professionals in the industry.

Related Topics:

Is Transportation A Good Career Path

Is Industrial Machinery/Components a Good Career Path

Is Metal Fabrication a Good Career Path

Is Miscellaneous a Good Career Path

Is Capital Goods a Good Career Path

Is Public Utilities A Good Career Path

Is Major Banks a Good Career Path

Career Options in Metal Fabrication

A career in metal fabrication offers diverse opportunities to specialize in various areas. Some common career paths include:

1. Welder

Welders are skilled professionals who use heat to join metal parts together. They play a crucial role in the metal fabrication process, creating everything from small machine parts to large structures. Welders can specialize in different types of welding, such as TIG, MIG, or stick welding, and can work in various industries, including construction, manufacturing, and shipbuilding.

2. Fabricator

Fabricators are the backbone of the metal fabrication industry. They cut, bend, and assemble metal components and structures. Fabricators need to be proficient in reading blueprints and using a variety of tools and machinery. They can work in a wide range of sectors, including automotive, aerospace, and construction.

3. CNC Operator

Computer Numerical Control (CNC) operators use computer-controlled machinery to cut, shape, and form metal parts. CNC machines can produce high-quality, precise components at a faster rate than manual machining. CNC operators need to understand computer programming and have a keen eye for detail.

4. Sheet Metal Worker

Sheet metal workers specialize in creating products from thin metal sheets. They might work on HVAC systems, roofing, siding, or other construction projects. This role requires precision and the ability to work with various tools and machinery.

5. Quality Control Inspector

Quality control inspectors ensure that the final products meet the required standards and specifications. They inspect, test, and measure materials or assembled parts or products for defects and deviations from specifications. This role requires a keen eye for detail and a thorough understanding of metal fabrication processes.

6. Metal Fabrication Engineer

Metal fabrication engineers design and develop metal parts and structures. They use CAD software to create blueprints and oversee the fabrication process to ensure the final product meets the design specifications. This role requires a degree in engineering and a strong understanding of metal properties and fabrication techniques.

Salary Range in Metal Fabrication

The salary range in metal fabrication can vary on factors such experience, specialization, location, and industry. Here are some average salary figures for common roles in the metal fabrication field:

- Welder: The average annual salary for welders from $35,000 to $60,000, depending on experience and expertise. skilled welders with specialized certifications or working in industries such as aerospace or nuclear power can earn even higher salaries.

- Fabricator: Fabricators typically earn an average annual salary of $40,000 to $70,000. Those with advanced skills in blueprint reading,, and CNC machining may command higher salaries.

- CNC Operator: The average annual salary for CNC operators ranges from $35,000 to $60,000. Operators with expertise in programming and operating complex CNC machinery may earn higher salaries.

- Sheet Metal Worker: Sheet metal workers earn an average annual salary of $40,000 to $70,000. Those with advanced skills in HVAC systems or architectural metalwork may earn higher salaries.

- Quality Control Inspector: The average annual salary for quality control inspectors in metal fabrication ranges from $40,000 to $70,000. Inspectors with additional certifications or experience in specialized industries may earn higher salaries.

Job Outlook in Metal Fabrication

The job outlook for metal fabrication professionals is generally positive. While automation and technological advancements have impacted some aspects of the industry, skilled workers are still in demand. Here are some key factors contributing to the positive job outlook:

- Industry Demand: Metal fabrication is a vital that serves various sectors, including construction, automotive, aerospace, and manufacturing. As long as these industries continue to grow and innovate, there will be a need for skilled metal fabricators.

- Replacement Demand: Many experienced metal fabricators are reaching retirement age, creating opportunities for new professionals to the field. This replacement demand, coupled with industry growth, contributes to job openings.

- Technological Advancements: While automation has affected certain aspects of metal fabrication, skilled workers are still required to operate and maintain advanced machinery. Professionals who can adapt to new technologies and possess specialized skills will have better job prospects.

- Global Infrastructure Development: The increasing demand for infrastructure development worldwide, including transportation systems, buildings, and energy projects, creates a steady demand for metal fabrication professionals.

How to Get Started in Metal Fabrication

If you are interested in pursuing a career in metal fabrication, here are some steps to help you get started:

- Research and Gain Knowledge: Familiarize yourself with the field of metal fabrication, its various processes, and the skills required. Understand the different career paths and specialties available.

- Acquire Relevant Education and Training: Enroll in vocational programs, technical institutes, or apprenticeships to gain formal education and practical training in metal fabrication. Develop your skills in welding, machining, blueprint reading, and other essential areas.

- Build a Portfolio: Create a portfolio showcasing your projects and skills. Include photographs or documentation of your work to demonstrate your capabilities to potential employers or clients.

- Gain Experience: Seek internships or entry-level positions in metal fabrication companies to gain hands-on experience. This will help you refine your skills, learn from experienced professionals, and expand your network within the industry.

- Continuous Learning: Stay updated with industry trends, advancements, and new technologies. Attend workshops, seminars, or online courses to enhance your knowledge and skills.

Challenges Faced in the Metal Fabrication Industry

While metal fabrication offers promising career prospects, there are certain challenges that professionals may encounter. Some common challenges in the industry include:

- Competition: The metal fabrication industry is highly competitive, and fabricators must continuously demonstrate their skills, quality of work, and ability to meet deadlines to stand out from competitors.

- Technological Advancements: Keeping up with rapidly evolving technologies and adopting new tools and techniques can be challenging. Fabricators need to invest time and effort in staying updated to remain competitive.

- Safety Risks: Metal fabrication involves working with heavy machinery, sharp tools, and potentially hazardous materials. Adhering to safety protocols and maintaining a safe working environment is crucial but can be demanding.

- Project Management: Managing multiple projects simultaneously, coordinating with clients, suppliers, and other stakeholders, and meeting project deadlines require strong organizational and communication skills.

- Physical Demands: The physical nature of metal fabrication work can be physically demanding, leading to fatigue and potential health risks if proper care and precautions are not taken.

Conclusion

Metal fabrication is indeed a good career path for individuals with an interest in working with metals and a passion for creating tangible objects. The industry offers a wide range of career options, job security, competitive salaries, and opportunities for growth and specialization. However, it’s important to be aware of the physical demands, the need for continuous learning, and the importance of safety in this field.

By acquiring the necessary skills, staying updated with technological advancements, and maintaining a commitment to quality and safety, aspiring metal fabricators can build a successful and fulfilling career in this dynamic industry. Whether it’s constructing towering structures, crafting intricate metal artwork, or contributing to sustainable solutions, metal fabrication provides a platform for creativity, growth, and professional development.

FAQs

- Q : What qualifications do I need to pursue a career in metal fabrication?

- A: While formal education is not always mandatory, acquiring relevant training and certifications in metal fabrication can enhance your job prospects. Vocational programs, technical institutes, and apprenticeships offer valuable education and hands-on training.

- Q: Is metal fabrication a physically demanding career?

- A: Yes, metal fabrication work can be physically demanding, requiring good physical stamina. It involves lifting heavy objects, standing for extended periods, and working in challenging environments. Proper safety measures and precautions are essential.

- Q: What is the job outlook for metal fabricators?

- A: The job outlook for metal fabricators is positive, with steady growth projected due to increasing demand in industries like construction, automotive, and manufacturing. Skilled professionals will be sought after to meet the ongoing infrastructure development and technological advancements.

Pingback: Is Industrial Machinery/Components a Good Career Path -

Pingback: How Many Jobs Are Available in Basic Industries -